Operations Strengthened by Environmental Responsibility

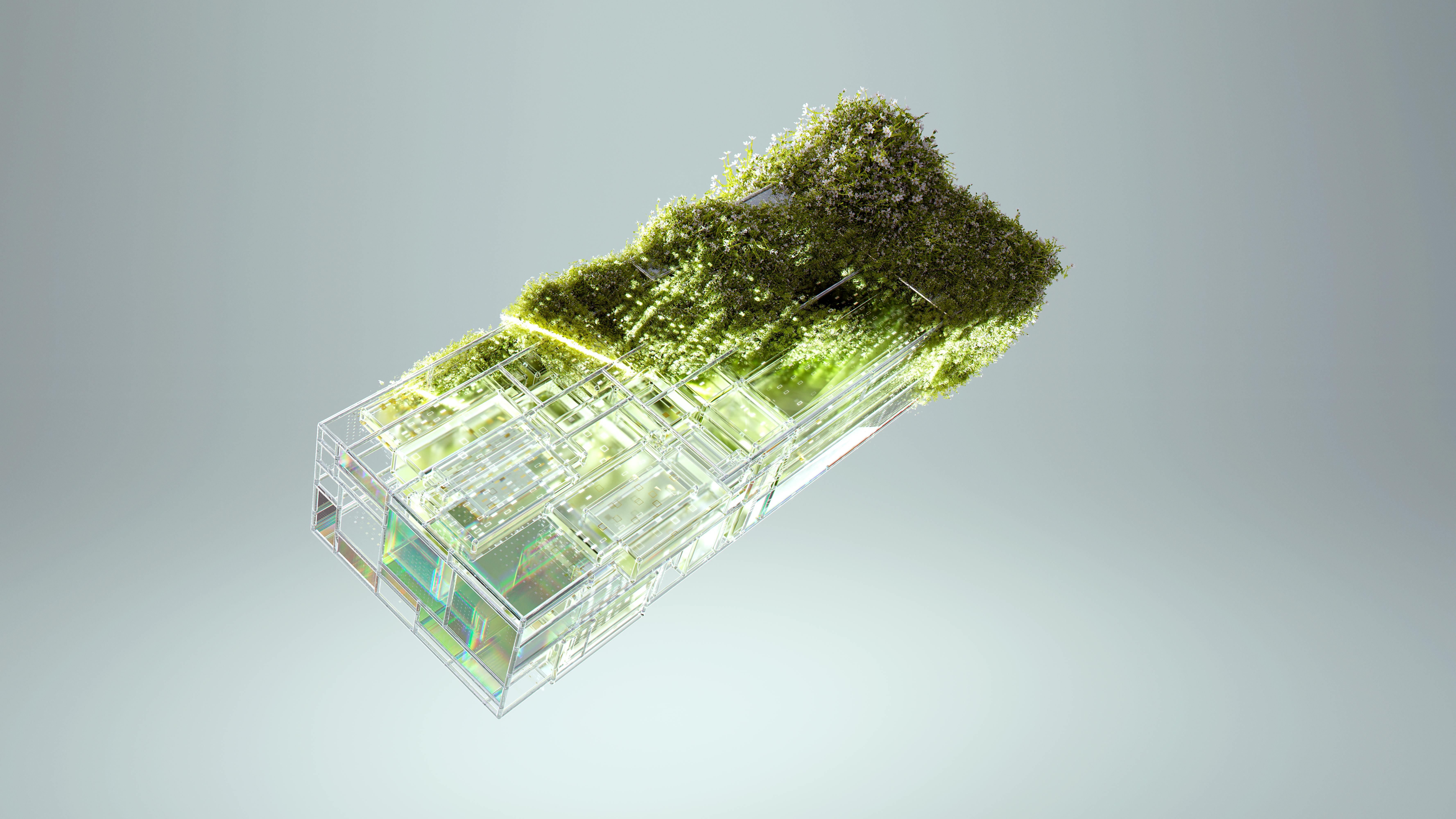

Bitumen supply is a fundamental component of global infrastructure investments. In this critical sector, we approach our operations not merely as a commercial activity, but as an integral part of our social and environmental responsibility. From energy efficiency to logistics optimization, and from emissions management to waste reduction, we design all our processes in alignment with sustainability principles. Our goal is to provide our partners with high-quality bitumen while reducing our environmental footprint, creating more efficient supply chains, and supporting responsible production–consumption models. Transparency, ethical business practices, and compliance with global standards form the foundation of our approach. Sustainability requires a business model that considers not only today’s needs but also those of future generations. Therefore, we prioritize working with all our stakeholders to build a more resilient, efficient, and environmentally friendly supply ecosystem.

- Reducing Environmental Impact

- Responsible Supply Chain Management

- Transparency and Ethical Product Approach

- Efficiency and Optimization in Logistics

- Social and Environmental Responsibility

Quality Management

Quality management is a fundamental factor that determines not only the characteristics of the product but also the reliability of the entire supply process. At every stage of the bitumen supply chain—including production, storage, loading, and delivery—we manage processes in compliance with international standards, ensuring consistent and high-quality products for our clients. From laboratory testing to document verification, and from loading inspections to logistics tracking, every step is supported by a transparent and traceable quality management system. Our goal is not only to guarantee product quality but also to provide our partners with a supply experience that fosters sustainable success in their operations.

Quality Certificates

Each product undergoes the necessary laboratory tests, and certificates, compliance with technical specifications, and reports are shared transparently.

Process-Oriented Quality Control

Every stage, from production to loading, is closely monitored, with multi-step control mechanisms implemented to ensure compliance with quality standards. Waste, loss, and risk levels are minimized.

Consistent and Reliable Operations

Logistics processes are optimized, and standardized operational protocols are implemented to ensure on-time shipments and damage-free deliveries.